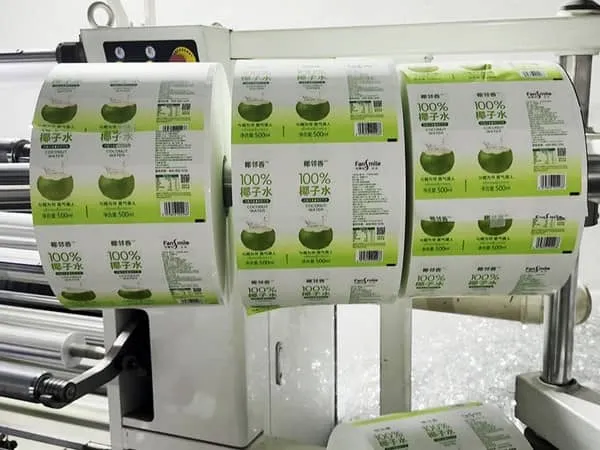

Zhongheng has over 10 years of experience in plastic labeling and run eight advanced production lines dedicated to shrink sleeves. All the production stages, including printing, lamination, die-cutting, inspection, and packaging, are managed in our own facilities, giving us better control over quality and delivery times.

Our stock of raw materials gives us the flexibility to handle urgent requests as well as large orders. Customers can choose from different label materials such as PVC, PETG, and OPS, depending on their requirements for the appearance of their finished products, environmental performance, or cost control. After shrinking, the labels fit closely to bottles and containers of different shapes, including curved and irregular ones. The result is a smooth finish without wrinkles or bubbles, showing the full shape of the container while also protecting the product.

| Material type | PETG, PVC, OPS |

| Thickness | 35–70 μm |

| Layflat width | 50–300 mm |

| Slit width | 100–600 mm |

| Label height / cut length | 30–300 mm |

| Core inner diameter | 76 mm (3 in.) |

| Shrinkage (TD) | 40–80% |

| Shrinkage (MD) | 0–10% |

| Shrink temperature range | 90–110 °C |

| Tensile strength | ≥ 40 MPa |

| Tear resistance | ≥ 70% |

| Transparency | ≥ 90% |

| Haze | ≤ 10% |

| Printing methods | Gravure, flexo, digital |

| Color options | Over 10 colors available |

| Surface finish | Glossy, matte, coated |

| Easy-tear / perforation | Optional |

| Anti-scratch coating | Optional |

| Environmental Features | Recyclable / Biodegradable |

Shrink sleeve labels are designed for a wide range of packaging needs. They are commonly used for:

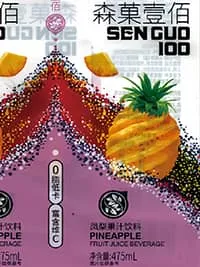

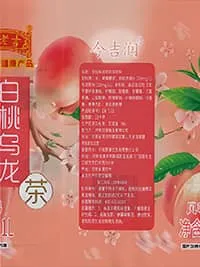

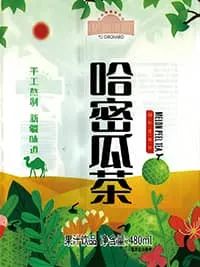

Shrink sleeve labels are widely used by alcoholic beverage companies, bottled water producers, soft drink manufacturers, household cleaning brands, dairy product companies, condiment and sauce brands, and even pet food packaging.

Shrink sleeve labels can be fully customized based on requirements. Options include material selection (PVC, PETG, OPS, with eco-friendly or food-grade certification available), printing methods, dimensions and shapes (custom widths, lengths, irregular die-cuts, shrink ratios), as well as functional finishes and post-processing features.

The 360° wraparound design provides full brand visibility and strengthens anti-counterfeiting protection. Labels adapt to different bottle shapes, remain waterproof and abrasion-resistant, and extend product durability. They also support high-speed automated labeling for improved efficiency, while premium printing effects and eco-friendly materials enhance brand image.

Shrink sleeve labels create a strong shelf presence with 360° coverage, adapting easily to various bottle designs including curved and irregular shapes. The labels are resistant to water, oil, and abrasion, while supporting high-resolution graphics and security features. They fit tightly after shrinking, resist peeling, reduce storage and transport volume, and improve both branding and packaging efficiency.

Labels improve product appeal and brand recognition with a close fit to container surfaces that ensures durability. They adapt to different packaging shapes, remain resistant to water and stains, and maintain a clean appearance. Efficient production processes also help reduce costs while ensuring consistent quality.

Providing one-stop services from original design and material selection to manufacturing and delivery

Serving more than 800 customers