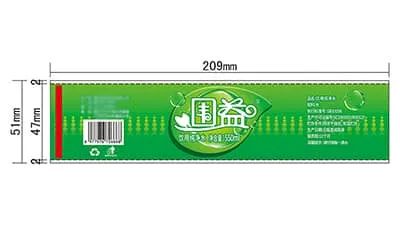

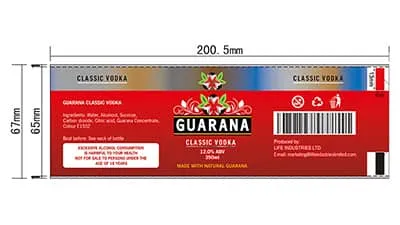

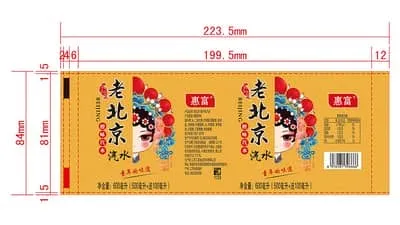

Zhongheng has extensive experience in producing custom hot-melt adhesive labels, delivering professional solutions for food and beverages, household products, and a variety of other applications. Labels can be tailored in terms of color, layout, size, and material, ensuring both attractive presentation and reliable functionality.

Our production lines work with materials such as PVC, PETG, OPS, and BOPP, supported by advanced printing, coating, and slitting equipment. With a daily capacity of up to 30 million labels, we are equipped to handle both large-scale and urgent orders. Every batch undergoes multiple tests, including tensile strength, abrasion resistance, and flatness checks, to ensure that each label adheres securely to its container and maintains long-term durability.

With high production capacity with uncompromising quality, our hot-melt adhesive labels not only secure your packaging but also strengthen your brand’s presence in a competitive market.

| Label material | Pearlized film, BOPP, multi-layer composite film |

| Label thickness | 40–120 μm |

| Adhesive type | EVA, PE, polyurethane (PU) |

| Adhesive coating thickness | 15–30 μm |

| Label size | Width and length customized as required |

| Adhesion strength | ≥ 2.0 N/cm (between paper and PET substrate) |

| Peel strength | 200–500 g/inch |

| Elongation | 10%–40% |

| Temperature resistance | –20 °C to +80 °C |

| Roll width | 330 mm / 420 mm / customized |

| Core inner diameter | 76 mm / 152 mm |

| Roll weight | ≤15 kg |

| Printing compatibility | Thermal transfer, flexographic, screen printing |

| Surface finish | Gloss, matte, textured |

| Adhesion method | Hot-melt adhesive activation |

| Adhesive set time | 1–3 seconds |

| Storage conditions | 20-25°C,dry and away from light |

| Shelf life | 6-12 months |

| Environmental compliance | RoHS、REACH |

We provide a selection of widely used materials for hot-melt adhesive labels, designed to meet the diverse needs of different industries and packaging formats:

Pearlized film labels: Ideal for carbonated drinks, energy beverages, bottled water, and dairy products. The soft, glossy finish enhances the overall look and feel of the packaging.

BOPP labels: Suitable for juice bottles, children’s drinks, shampoo, body wash, and other household products. These labels are resistant to abrasion and tearing, making them reliable in high-frequency use environments.

Multi-layer composite film labels: Designed for condiments such as soy sauce, vinegar, chili paste, and ketchup, as well as large-capacity bottles and special packaging. These labels combine barrier properties with durability, making them suitable for complex packaging conditions.

Let's create custom labels that elevate your product packaging.

When bottles get damp or condensation builds up, the glue doesn’t stick as firmly as it should and may soften, causing the label edges to lift or peel away. To keep labels firmly in place, many brands use a thin protective film or add waterproof finishes, so that the labels stay neat and secure, even if the surface of the bottle is damp.

If the right balance of glue and heat is used, the labels stick properly, without leaving messy residue or affecting the surface of the bottle. Problems usually come up when the heat is set too high or when too much glue is applied, which can make the adhesive spill over and leave stains.

The environmental impact of labels mainly depends on the materials and adhesives used. Choosing recyclable films and glues that can be removed easily during recycling makes the process smoother and helps reduce waste. Using eco-friendly options is a good way to lower the overall footprint.

If materials and adhesives are not certified for food safety, extreme temperatures may release gases or migration substances that affect taste or safety. To avoid this, certified food-grade materials and adhesives should be used, tested under heating and cold-storage conditions to ensure no harmful release.

Yes, different packaging materials affect adhesion in different ways:

Providing one-stop services from original design and material selection to manufacturing and delivery

Serving more than 800 customers