With more than 10 years of experience in the labeling industry, Zhongheng has built a strong foundation of expertise and capacity. Today, we operate eight fully automated production lines that cover every stage of the process from printing, slitting, inspection, and packaging, supported by high-speed printing presses and precision cutting equipment.

Our facilities are designed to handle a wide range of materials and multi-color printing requirements with efficiency and consistency. We maintain a stable inventory of raw materials, allowing us to respond quickly to urgent requests and ensure on-time delivery.

Available processing materials include PVC, PETG, OPS, and BOPP, as well as multi-layer composite structures. The company’s production capacity is supported by 8 printing machines, 8 slitting machines, 6 forming machines, and 8 sets of testing equipment, enabling a daily output of up to 30 million labels.

We choose to work only with trusted suppliers who have more than 30 years of experience in the industry. Both our inks and film-based materials are carefully sourced to guarantee stable quality and reliable performance in every production run.

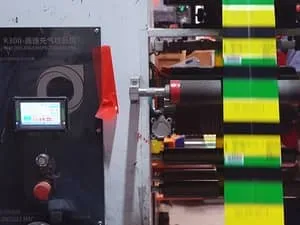

We operate 8 high-performance printing machines, each equipped with online inspection and automatic feeding control systems. This ensures consistent quality and efficiency throughout our label production. A single machine can produce 5 to 6 million labels per day, supporting an overall daily output of around 30 million labels across shrink sleeve and hot melt adhesive products. To maintain precision, every batch is inspected both during and after printing, enhancing quality levels by an estimated 50–60%.

Labels of different sizes are slit with high-speed precision equipment running at 300 pieces per minute, with a daily output of 3 to 4 million labels.

For sleeve-type labels, our forming machines align and seal labels accurately to ensure proper sizing and seamless application.

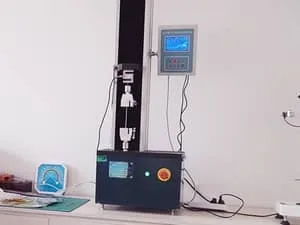

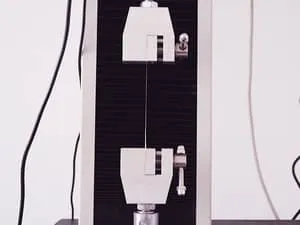

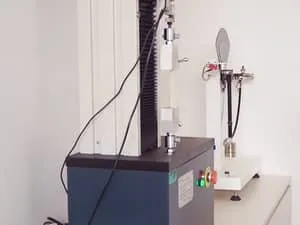

To ensure the stability and reliability of printing results and label performance, Zhongheng has established a comprehensive quality control system. This includes print sampling and inspection, tensile strength testing, impact resistance testing, abrasion testing, and flatness testing, each verifying key aspects such as material strength, durability, and surface stability.

We also operate advanced online inspection systems capable of detecting up to 95% of potential defects, ensuring consistent quality throughout the process. Every batch is inspected both during and after printing, so customers receive labels that are dependable and ready for use.

Labels are packaged according to customer requirements.

Zhongheng has over 10 years of experience in plastic labeling and run eight advanced production lines dedicated to shrink sleeves.

Zhongheng has extensive experience in producing custom hot-melt adhesive labels, delivering professional solutions for food and beverages, household products, and a variety of other applications.

Providing one-stop services from original design and material selection to manufacturing and delivery

Serving more than 800 customers